DST-36D Pallet (Built-in Work) Changer Tapping Center

The DST-36D model with its automatic pallet changing system, eliminates downtime caused by part removal and fastening. While parts are being processed on the first pallet, parts to be processed next are fastened and prepared on the second pallet. The pallet rotates precisely, ensuring accurate positioning with a gear coupling.

- 15,000 rpm and 24,000 rpm spindle options

- High pressure internal water supply system options

- Compatibility with robots and ease of use

Turning Diameter Max. 1.100 mm

Workpiece Height Max. 320 mm

Table load capacity 2X250 kg

Workpiece Height Max. 320 mm

Table load capacity 2X250 kg

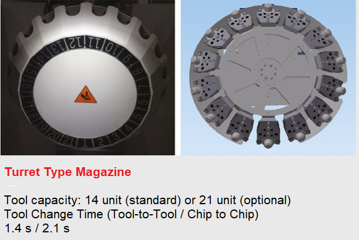

Turret Type Magazine

Tool capacity: 14 unit (standard) or 21 unit (optional)

Tool Change Time (Tool-to-Tool / Chip to Chip) 1.3 sec / 1.9 sec

Tool capacity: 14 unit (standard) or 21 unit (optional)

Tool Change Time (Tool-to-Tool / Chip to Chip) 1.3 sec / 1.9 sec