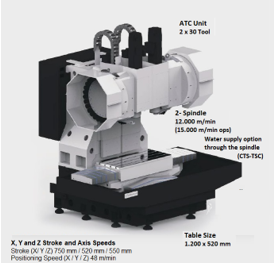

E50DM Dual-spindle tapping center

The Nomura DS E50DM model CNC tapping centres are compact and optimally designed for maintenance, automation and layout. Robot integration is extremely easy thanks to automation support functions. The machine interface is designed to be operator friendly, ergonomic, easy to learn and easy to use control panel.

- 12.000 RPM, 15.000 RPM and 24.000 RPM spindle options

- BBT40 spindle nose standard and tool taper

- Two Independent Spindles (2 Separate Offsets)

- Independent movement drive and control on the Z and W axis

- Easy tool setup

- High-pressure internal coolant system options

- Compatibility with robots and ease of use

.png)

- ATC Unit 2 X 30 Tool

- 2 Spindle 12.000 m/min (15.000 m/min ops.)

- Water Supply option through the spindle (CTS-TSC)

- Table Size 1.200 X 520 mm

- X, Y, Z and W Stroke and Axis Speeds

- Stroke (X / Y / Z / W) 750 mm / 520 mm / 550 mm / 550 mm

- Positioning Speed (X / Y / Z / W) 48 m/min

Techical Specifications

Provides efficient and optimum benefits in all types of milling and drilling operations. Designed for multifunctional tapping center applications that require maximum precision, dynamics and reliability and can be customized with additional equipment.

| NOMURA-DS | E50DM |

|---|---|

| TRAVEL | |

| X-Axis | 750 mm |

| Y-Axis | 520 mm |

| Z and W (INDEPENDENT-2 SEPARATE OFFSET) | 550 mm |

| Max.-Min Distance Between Table Surface and Spindle Face | 800 mm - 250 mm |

| TABLE | |

| Table Size | 1.200X520 mm |

| Maximum Loading Capacity | 800 kg |

| AUTOMATIC TOOL CHANGER UNIT | |

| Tool Changing System / Magazine Tool Capacity | Twin Arm / 30 Tools |

| Maximum Tool Diameter / Tool Weight / Tool Length | Ø78 mm / 8 kg / 300 mm |

| Tool Change Time (Tool to Tool) / (Chip to Chip) | 3,1 sec / 4,5 sec |

| SPINDLE | |

| Max Speed | 12.000 m/min / (15.000 m/min ops.) |

| Spindle Taper (Tool Shaft Interface) | No 40 / BBT40 |

| Spindle Motor Maximum Power/Torque | 18,5 kW / 118 Nm |

| AXIS SPEEDS | |

| Positioning Speed (X / Y / Z / W) | 48 / 48 / 48 / 48 m/min |

| MACHINE DIMENSIONS | |

| Floor Space / Height | 2.800 mm X 2.735 mm / 3.452 mm |

| Weight | 8.500 kg |