NOMURA DS DST-40L

The Nomura DS DST-40L CNC single spindle tapping centers are compact and optimally designed for maintenance, automation and layout. Robot integration is extremely easy thanks to automation support functions. The machine interface is designed to be operator friendly, ergonomic, easy to learn and easy to use control panel.

- 15.000 RPM and 24.000 RPM spindle options

- High pressure spindle through water supply system options

- Compatibility with robots and ease of use

Techical Specifications

Provides efficient and optimum benefits in all types of milling and drilling operations. Designed for multifunctional tapping center applications that require maximum precision, dynamics and reliability and can be customized with additional equipment.

| NOMURA-DS MODEL | DST-40L |

|---|---|

| TRAVEL | |

| X-Axis | 720 mm |

| Y-Axis | 400 mm |

| Z-Axis | 350 mm |

| Max.-Min Distance Between Table Surface and Spindle Nose | 500 mm - 150 mm |

| TABLE | |

| Table Size | 850X400 mm |

| Maximum Loading Capacity | 300 kg |

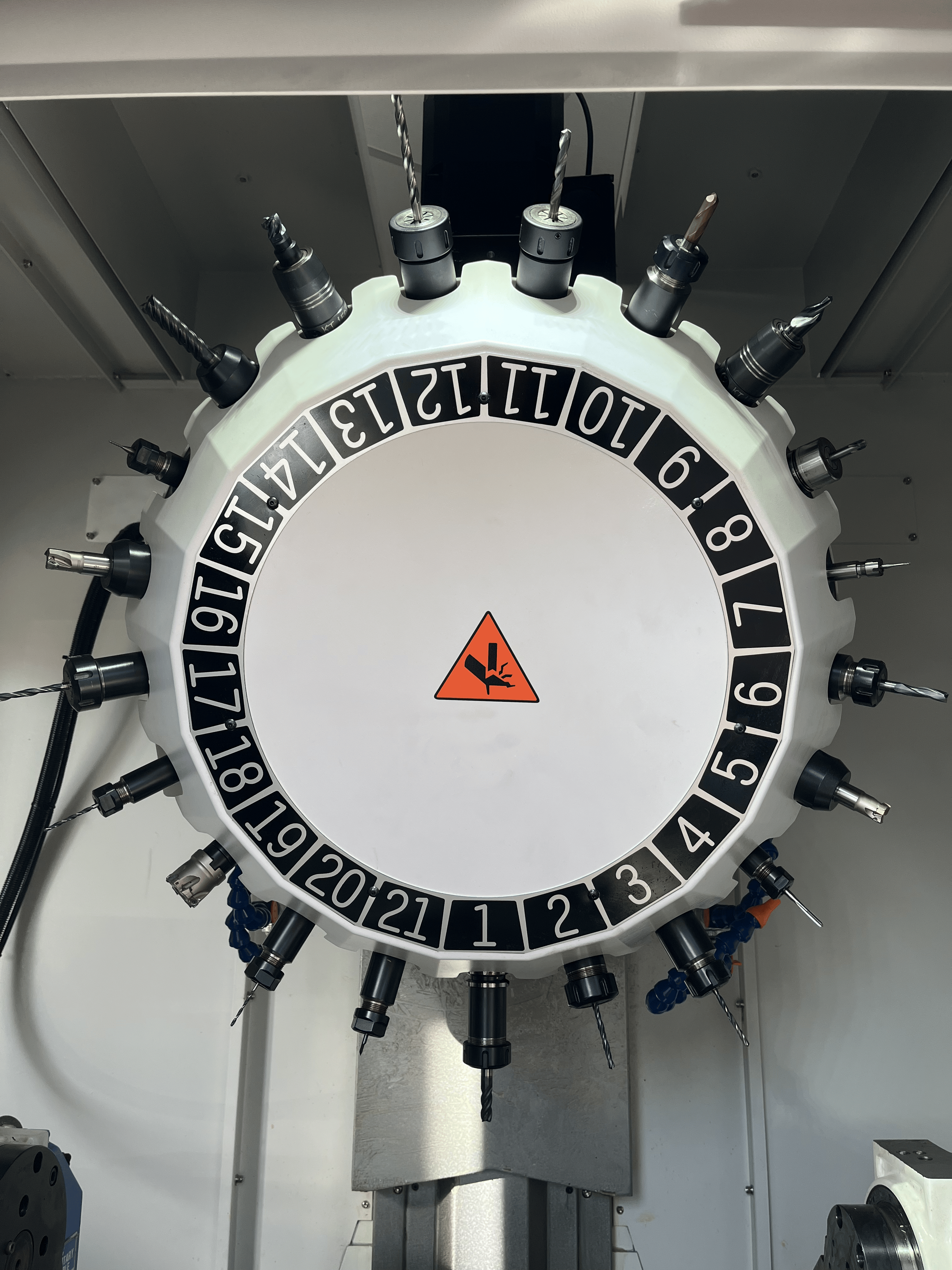

| AUTOMATIC TOOL CHANGER UNIT | |

| Tool Changing System / Magazine Tool Capacity | Turret type / 21 sets |

| Maximum Tool Diameter / Tool Weight / Tool Length | Ø80 mm / 2,5 kg/tool (total 33 kg)/ 200 mm |

| Tool Change Time (Tool to Tool) / (Chip to Chip) | 1,3 sec / 1,9 sec |

| SPINDLE | |

| Max Speed | 15.000 RPM / (24.000 RPM ops.) |

| Spindle Taper (Tool Shaft Interface) | 7/24 Conical No 30 / BBT30 |

| Spindle Motor Maximum Power/Torque | 7,5 kW / 84,3 Nm |

| AXIS SPEEDS | |

| Positioning Speed (X / Y / Z / W) | 60 / 60 / 60 m/min |

| MACHINE DIMENSIONS | |

| Floor Space / Height | 2.150 mm X 2.071 mm / 2.736 mm |

| Weight | 3.100 kg |